Elevate Your Efficiency. Experience the Benefits of ABM:

Automates the complex process of building and depleting inventory buffers throughout your facility.

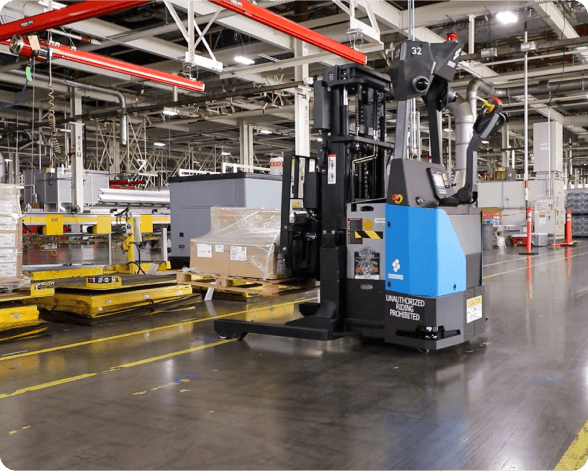

Best-in-Class Payload Detection

Both Lift CR1 and Lift RS1 pick and move the widest variety of payloads with the most robust and effective payload detection capabilities on the market.

Seamless Integration

Utilizing Fleet Central—Seegrid’s user-friendly fleet management software—customers can easily integrate with PLC devices, WMS/ERP/MES and barcode scanners for unmatched flexibility.

Industry-Leading Safety

Equipped with Seegrid's advanced tech stack, proprietary computer-vision technology, a suite of primary and secondary safety sensors, and advanced payload detection, Seegrid AMRs operate safely with precision and reliability.

Trusted by Top Industry Leaders

Key Buffer Zones for Seegrid’s ABM

ABM is designed to automate essential buffer management workflows across the material handling spectrum. By automating buffer management with Seegrid’s Lift AMR solutions, you can expect unparalleled efficiency and predictability.

WIP Storage Buffers

Effectively manage partially completed products or materials that are awaiting further processing or assembly.

Cross-Docking

Facilitate the sorting, staging, and sequencing of incoming shipments for efficient outbound processing.

Shipping and Receiving

Streamline the movement of materials between shipping and receiving areas for a seamless flow of goods.

Parts-to-Line

Enable smooth assembly workflows and minimzed downtime with a reliable supply of materials ready for use.

Delivering More

Quick Answers to Some Frequently Asked Questions.

Can't find what you're looking for?

Storage, cross docking, shipping and receiving, and parts-to-line buffer zones are all great fits for ABM, but if you've got a buffer, we can manage it!

Explore Resources

Seegrid Unveils Lift CR1 Autonomous Lift Truck at MODEX '24

The Lift CR1 AMR boasts an impressive 15’ lift height and a robust 4,000lb payload capacity. Its cutting-edge technology redefines the possibilities for warehouse automation, offering a flexible and scalable solution to meet the diverse needs of modern facilities.

Autonomous Buffer Management for Transformative Material Handling

Seegrid announces the groundbreaking release of Autonomous Buffer Management (ABM), revolutionizing the way warehouses, manufacturing, and logistics facilities automate pallet and other payload-based inventory buffers to optimize their mission-critical workflows.

Seegrid Unveils AMR Interoperability

With new advancements in perception technology, Seegrid Lift Truck AMRs is able to work directly with Tow Tractor to load and unload carts, which has previously been a time-consuming and labor-intensive workflow