Leading Autonomous Vehicle Safety By:

Reducing

Hazards

Autonomous vehicles are redefining safety in manufacturing and warehousing by replacing one of the greatest sources of risk—manual forklift operation—with consistent, rules-based autonomy for safer, more controlled workflows.

Supporting

Fork-Free Initiatives

Seegrid AMRs empower facilities to strategically plan, coordinate, and manage forklift activity—streamlining the execution of fork-free initiatives that enhance safety and significantly reduce risk on the facility floor.

Earning Your Trust,

Mile After Mile

With over 18 million autonomous miles driven across more than 200 customer sites, Seegrid AMRs have operated without causing a single OSHA-recordable incident—showcasing its reliability in dynamic, real-world environments.

BUILT FOR SAFETY, ENGINEERED FROM THE GROUND UP

The Seegrid Approach to Safety

At Seegrid, safety isn't just a feature—it’s the foundation of everything we build. Our approach is guided by four non-negotiable principles that drive every autonomous solution:

Seegrid AMRs replace one of the most variable and high-risk elements in palletized material handling—manual vehicle operation—with predictable, rule-based autonomy to create safer, more stable industrial environments.

The Seegrid Difference

Layered

Safety Sensing

Our AMRs feature advanced, layered 2D and 3D LiDAR technologies to deliver full path and payload awareness—enabling safe, reliable performance in modern dynamic environments.

Real-World

Implementation Success

Technology alone isn’t enough for a fully successful autonomous solution. Our expert team ensures each solution is fully integrated, adopted onsite, and drives safety where it matters most—on the facility floor.

Long-Term

Operational Support

The first 100 days set the tone, but long-term success depends on the next 1,000. We’re your long-term partner, supporting autonomous systems that run safely, reliably, and at scale.

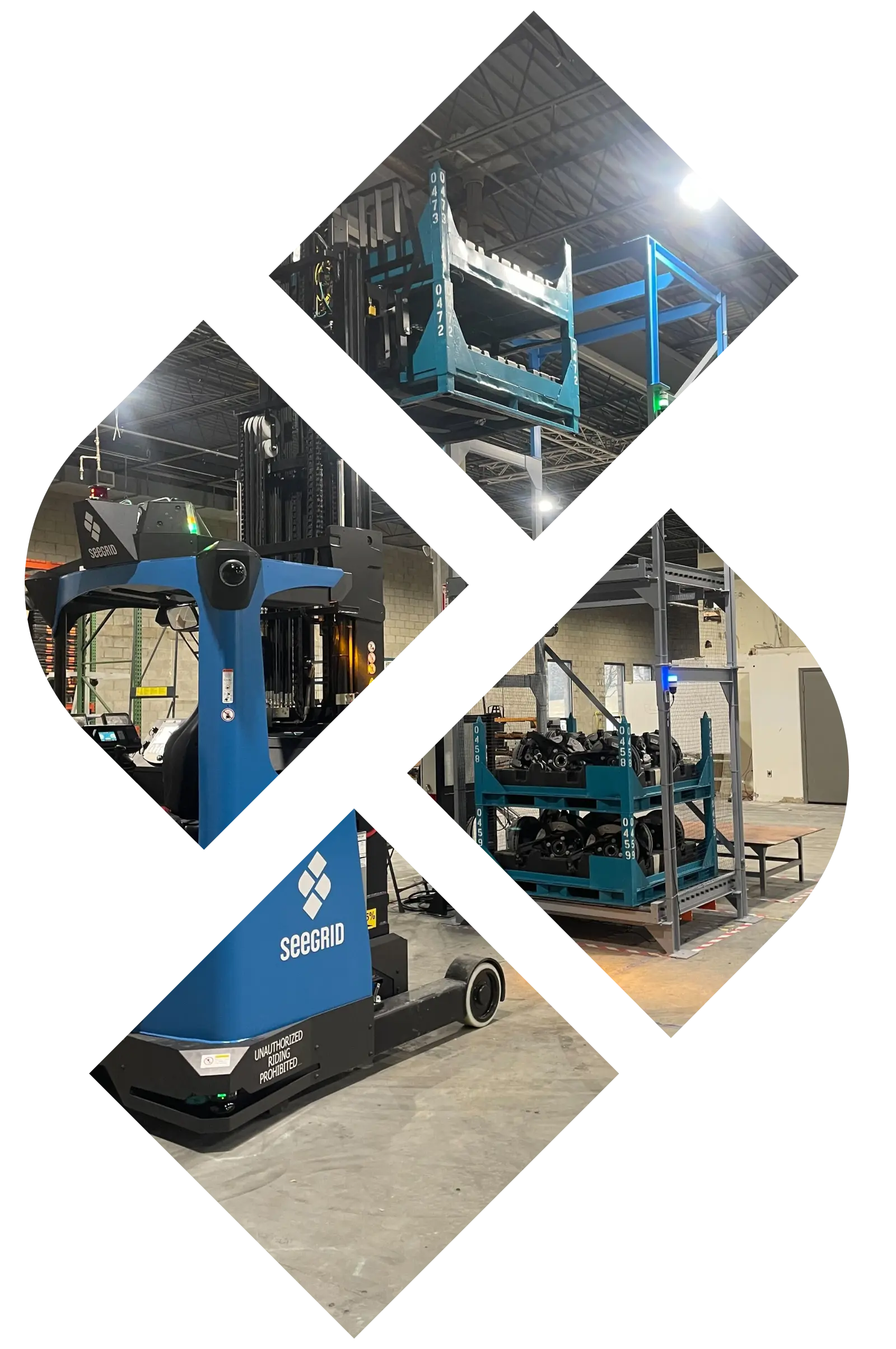

Meet Our AMR Fleet

Optimize facility workflows and transform material handling with Seegrid AMRs, enhancing productivity and reducing costs through seamless, connected autonomous solutions.

Lift CR1 AMR

Seegrid's newest AMR boasts an industry-leading combination of height and capacity as it easily handles a wide range of material handling challenges including: Autonomous Buffer Management (ABM), material transport, vertical handling, and placement of goods and parts to line.

4,000 lb Payload Capacity

5 mph Max Speed

Designed for low-lift processes such as Autonomous Buffer Management, parts to line, outbound, and cross docking across manufacturing and logistics facilities, the RS1 provides seamless workflow automation that delivers unmatched efficiencies and productivity gains.

6' Lift Height

3,500 lb Payload Capacity

5 mph Max Speed

Tow Tractor S7 AMR

Predictably transport cart trains and other heavy payloads using Seegrid's most proven and battle-tested form factor—the Tow Tractor—ideal for parts-to-line, replenishment, putaway, long-hauls, trash removal, cross docking applications, and more.

10,000 lb Load Capacity

4 mph Max Speed

18M+ Autonomous Miles Driven