Proven Autonomy.

Built for Industry. Scalable for the Future.

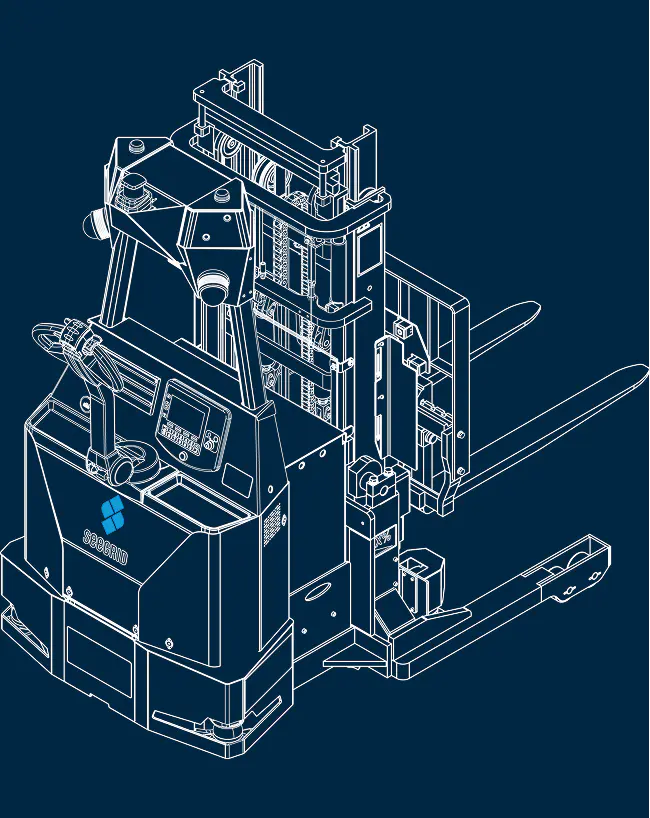

Over 20 years ago, Seegrid pioneered the core infrastructure-free localization and mapping technologies that define autonomous navigation in material handling today. Building on that legacy, our autonomous lift trucks have established the standard in pallet manipulation. Our commercial-grade autonomy is the most capable in the market-hardened for real-world environments and designed to effortlessly integrate with existing operations, not work around them.

Our Core Technology

01 Perception

02 Planning

03 Execution

01 Perception

02 Planning

03 Execution

Watch Our Innovations Unfold

Technology That Adapts and Evolves

Seegrid Sets the Standard with Industry-Leading Forklift AMR Payload Versatility

Seegrid's advanced AMRs are uniquely equipped to handle the most payloads in the modern manufacturing industry today, from standard pallets to customer-specific forkables-any pallet or payload intended to be handled with a fork truck-with high variation in shape, size, and material composition.

Autonomous Buffer Management for Transformative Material Handling

Seegrid announces the groundbreaking release of Autonomous Buffer Management (ABM), revolutionizing the way warehouses, manufacturing, and logistics facilities automate pallet and other payload-based inventory buffers to optimize their mission-critical workflows.

Seegrid AMRs Surpass 17 Million Autonomous Miles Driven in Customer Facilities

Seegrid announced a major milestone: its AMRs have surpassed 17 million autonomous miles driven in production at customer sites. This achievement validates Seegrid's commitment to delivering safe, scalable autonomous solutions that work day in and day out for some of the world's largest and most demanding manufacturers, distributors, and e-commerce providers.